Joraco Press Company has been an innovator of benchtop air press machines for over 75 years

We are not only innovators in the press industry, we specialize in the most precise, efficient, and economical pneumatic presses, Made in the USA!

Contents

What is a Pneumatic (Air) Press?

Benchtop pneumatic presses offer a range of benefits in a wide range of applications. These machines are great due to their:

- Size

- Speed

- Efficiency

- Simplicity

Pneumatic presses generate a force greater than manpower (with a manual press, usually known as an arbor press) alone can supply. It can be used for pressing, squeezing, forming, and other actions. This removes the potential for repetitive strain on the operator, increasing efficiency, and repeatability resulting in better quality parts and reducing costs over time.

The potential force of a pneumatic press comes from compressed air pressing against a piston inside an enclosed cylinder; the area of the piston multiplied by the air pressure determines the force generated by the press. The actuation of the press comes from either an air or electric signal, typically generated by an operator when running manually, or by a PLC in an automated system setup. The signal to the press can be configured to create a complete cycle for each signal sent. It also can be configured for Constant Signal Required (CSR), whereby the operator is required to maintain the input signal for the press to actuate, staying down, applying force until the operator removes the signal, then the press retracts. Operators typically use a two hand, anti-tie down controller which requires simultaneous hand operation to insure the operator’s hands are free from the work area and potential risk of injury. PLC actuated systems utilize sensors and physical/light curtain guarding to insure operator safety.

Direct, double-acting pneumatic presses are the most widely used type in industrial applications. These types of presses use air to advance and retract the cylinder, which is beneficial for applications with heavy tooling attachments, and applications that require quick response and cycle times.

Common Press Applications

Assembly is one of the most common applications and benefits the most from benchtop precision presses. All of our products aid in the assembly process of millions of parts, but with the help of a rotary indexing system, our INDEX-AIRE™ Series makes quick work of repetitive tasks!

Also, Compressing, Calibrating, and Heat Stamping

Whether you are using steel rule dies or custom die sets, Joraco Presses are well-suited for die cutting applications. You may need the ultra-precision and depth control of the TOGGLE-AIRE® Series, but our DIRECT-AIRE® Series provides and economical and configurable press for applications under 5 Tons.

Also, Degating, Stamping, and Shearing

Joraco Press Company presses are well suited for all types of crimping applications, from hoses, tubes, and ferrules, to sheet metal, plastic, and rubber. The TOGGLE-AIRE® Series features ultra-precise depth control, making it perfect for intricate and delicate parts.

Also, Joining, Staking, and Forming

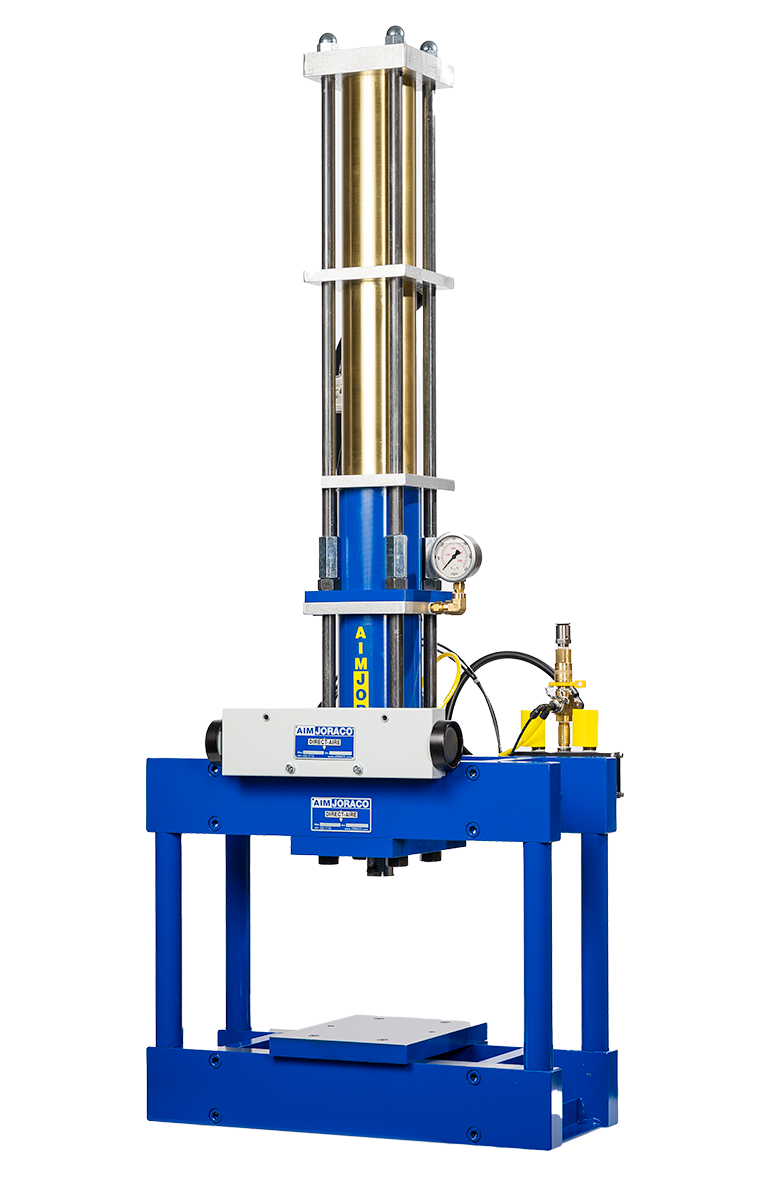

Press-fit applications require more force than manual insertion, but not so much that it can damage precision parts. With its automatic Stroke Adjustment and Power Stroke, the HYDRO-AIRE™ Series presses are perfect for press-fitting bushings, bearings, and pins.

Also, Pressing, Compacting, Swaging

Joraco Press Company can outfit our TOGGLE-AIRE® Series and INDEX-AIRE™ Series presses with feeders and bowls to provide a turnkey rivet solution for your high volume fastening applications. See more in our Application - Riveting page.

Also, Fastening, Marking, and Piercing

Pneumatic Press Families

TOGGLE-AIRE® Series

Precision and Power in a benchtop size. Ranging from 3 Tons to 32 Tons.

DIRECT-AIRE® Series

Economical and Customizable up to 5 Tons of force along the entire stroke.

HYDRO-AIRE ™ Series

Clean, quiet, and reliable up to 30 Tons. Featuring an Automatic Power Stroke!

What is a Toggle Press?

TOGGLE-AIRE® Series presses combine the mechanical advantages of levers and toggles. Forces produced don’t rely on ram impact; rather, it builds as the ram reaches the bottom of the stroke, and effects a shockless, powerful squeeze, regardless of ram speed. Additionally, it is highly efficient- a TOGGLE-AIRE® Series Model 1030 press is 300% more powerful than a comparable cylinder-sized DIRECT-AIRE® Series press, yet only 58% of the air is needed. Most importantly, the stroke is very precise with +/-.001” repeatability.

The Joraco Press line features simple pneumatic operation and convenient benchtop sizing using only readily available shop air up to 100PSI. Following the original Joraco TOGGLE-AIRE® Series, Joraco Indexers began integrating the mechanical advantage of the toggle press into a rotary index format to expand throughput. More recently, the DIRECT-AIRE® and HYDRO-AIRE™ Series model lines joined the TOGGLE-AIRE® to provide a range of useful sizes and applications for Joraco. The entire line is now available in various configurations and forces that can be customized for any industry and application.

Your Partner in Manufacturing

Joraco Press Company and Automated Industrial Machine, Inc have decades of experience designing and building custom press machines for every industry. Our US-based manufacturing facility has engineering, machining, and assembly operations all under one roof! We are flexible and equipped to customize any of our standard products, as well as design custom products from the ground up.

Nearly 70% of our presses are shipped with some form of customization, whether it is the addition of Packages, Options, or Accessories, or it is a complete multi-head automated assembly system. Our value-added approach to Manufacture-to-Order machine building puts us ahead of our competition in cost, customization, and delivery.