Shearing

An example of our work:

Joraco Press Company's Punch & Shear Application Using Servo Driven Feeder

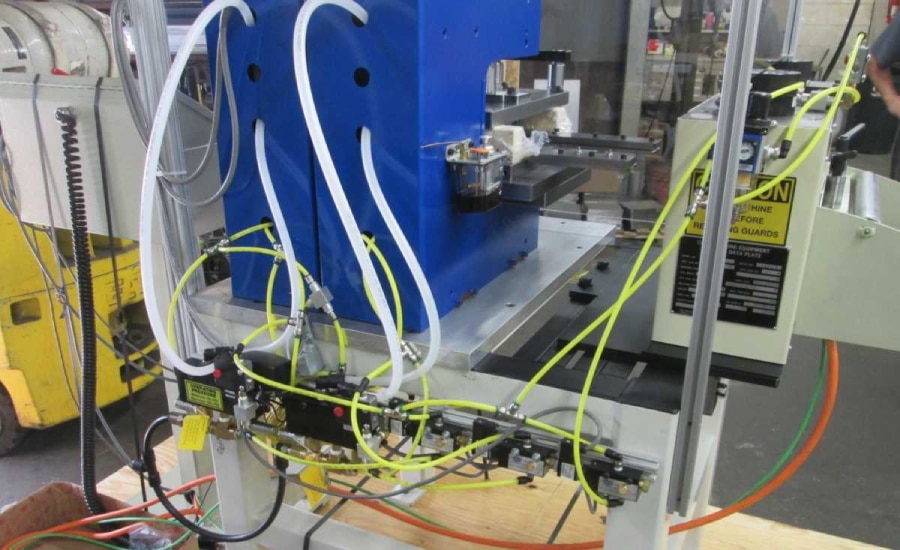

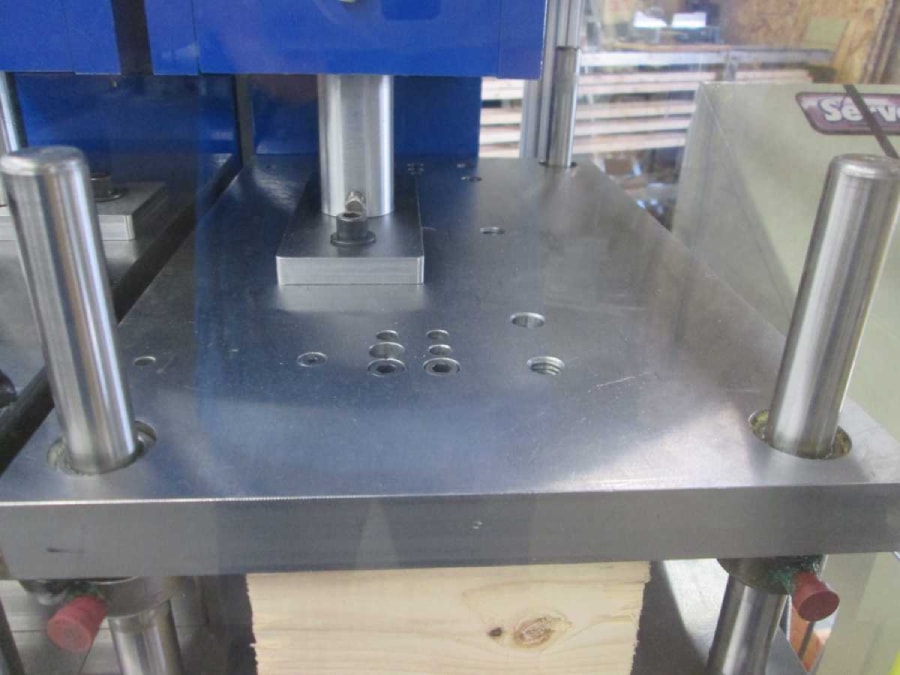

Joraco Press designed and built the fully automated multi-press punch and shear system for the manufacturing of transformer core sheets. It featured two high-accuracy 10-ton TOGGLE-AIRE® Series Model 2530 pneumatic presses, one for punching the hole and the other for shearing the sheet. The primary challenge of this project involved obtaining precise tolerances of ±0.002″ around the burr of the punched hole on the steel sheet. To ensure dimensional accuracy in the customer’s stack core transformer design, our engineers had to design, build, and exhaustively test the punch tools to ensure they repeatably produced holes with the correct size and shape.

Constructed from cold rolled steel for strength and rigidity, the automated punch and shear system features a space-saving 29.5″ long x 30.75″ footprint. Along with the two presses, it incorporated a servo feed that delivers precise positioning accuracy and enables the press to produce consistent parts with close tolerances at fast operating speeds. The punch and shear system also included an integrated PLC system that was fully programmed and ready to run as soon as the customer loaded up the material.

Joraco Press Company supplied this automated fabrication system with a precision sharpened carbide tooling package. The tooling successfully obtains precise tolerances, and with carbide’s ability to maintain its cutting edge, even during high speed punching, it produces accurate parts over long production runs.