Staking

An example of our work:

Staking Workstation for Supplier of High Quality Laser Engraved Pet ID Tags

A supplier of high-quality laser engraved pet identification products approached Joraco Press Company about the possibility of furnishing a turnkey staking system for the forming of anodized metal into several specific dog tag profiles.

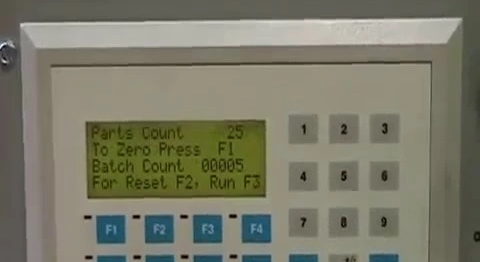

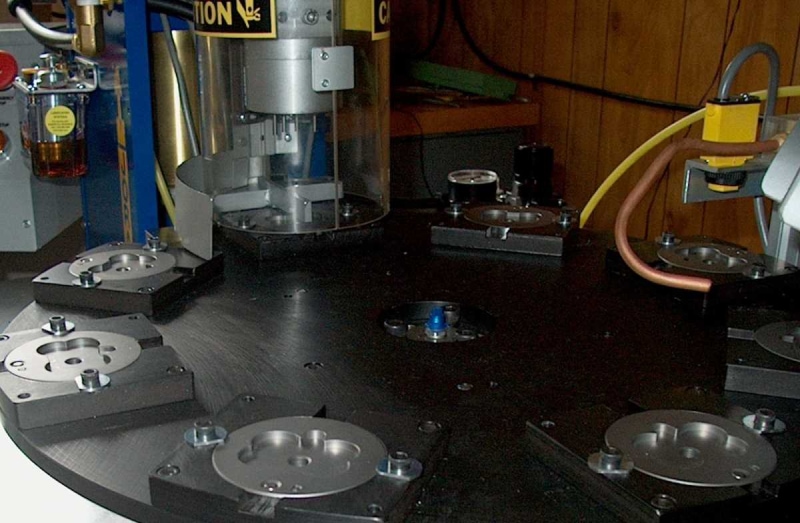

This turnkey workstation incorporates a staking press with custom tooling; a servo-powered rotary indexer and an air driven ejection system. After the operator loads blanks onto a rotary indexer with custom nests for each of the seven different profiles, the indexer moves the parts under the press where they are staked. Staked parts rotate to the ejection station where they are blown out of the nest by a pneumatic cylinder and into an ejection chute.

We built this automation system for continuous duty operation. At the customer site, it runs 24 hours/day for the mass production of pet identification tags with overall dimensions of 2.5″ in diameter x 0.1″ in thickness. The servo motor on the rotary indexer allows for flexible, high accuracy positioning to obtain repeatable accuracy of ±0.001″ on the finished tags. The customer was so impressed with the speed, accuracy, and repeatability of this system that they placed an order for four additional machines.