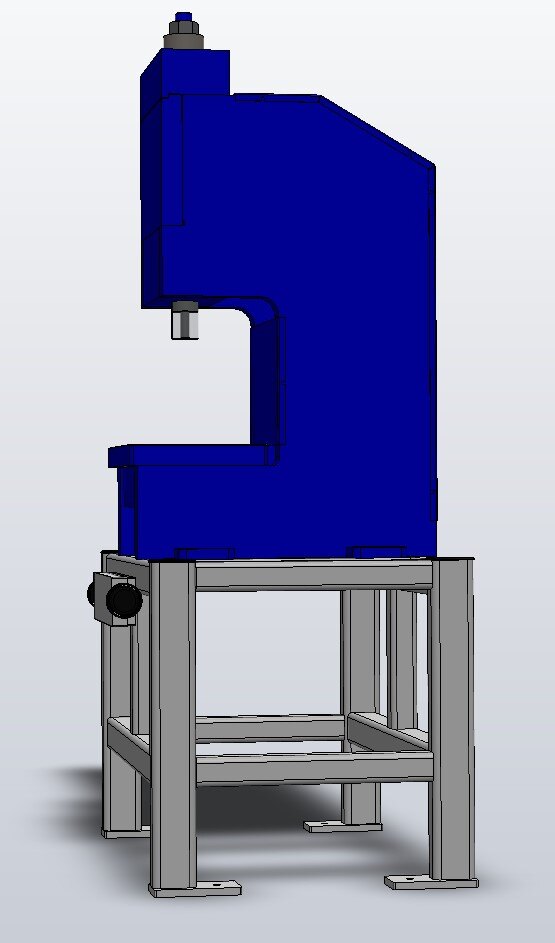

TOGGLE-AIRE® Series Model 8500

Joraco Press Company is proud to announce the newest addition to the TOGGLE-AIRE® Series press line- The Model 8500, the most powerful toggle press in its history. The Model 8500 develops only the amount of force needed to perform the work when the shut height is set for the part. The press will also maintain tool depth control to a tolerance of +/-.001" repeatable with every stroke. Although it is capable of tremendous forces from a standard 100 PSI air supply line, it can also perform the most delicate operations that require precision over power.

The size and capabilities of the new Model 8500 puts it in a great position as a replacement for many mechanical flywheel presses in manufacturing. It can be configured as a stand-alone press or configured into an assembly work cell. Applications such as Staking, Swaging, Clinching, Riveting, Punching, and Stamping are all well-suited for the Model 8500, but it can be tooled and fixtured to perform a multitude of operations without a concern for damaging delicate parts. Using its innovative toggle linkage design and the principle of reaction forces, the Model 8500 will use as little or as much of the available force to complete the job.

Available in Three Configurations:

- Pneumatic Logic Control

- Electronic Logic Control

- PLC-Ready 24v DC

For Options and Customizations, Request a quote below:

Due to the increased forces and larger cylinder, Joraco engineered a new press frame from 2" cold rolled carbon steel that was further machined to precision dimensions. Additionally, the Model 8500 comes mounted on its own custom floor stand rated for its weight and forces. With supplied adjustable feet, the work area is placed at a natural height for most operators.

For rigidity and precision, the massive frame is further machined after assembly and bolster plate mounting points are surface ground for ultimate control over the accuracy and repeatability of the work area. Standard bolster plates are 14" x 10" and are also precision ground for flatness.

The hand assembled pneumatic cylinders feature lathed and honed brass with machined 6061 aluminum end plates. Links, levers, and pins are hardened and treated for durability. The chrome plated ram is guided by press fit brass bushings, and the whole linkage system is lubricated using the standard One Shot Lubrication system mounted on the frame. The pneumatic valves and fittings are of the highest quality and are generally universal to promote repairability and prevent obsolescence.

|

Actual Footprint w/Stand: |

33” W x 22.5” D |

|

Recommended Available Floor Space: |

39” W x 29” D w/Stand |

|

Height: |

40.5” |

|

Height w/Stand: |

Variable depending on requested working height and footing options |

|

Width: |

19” including valving |

|

Depth: |

25.66” including valving |

|

Weight: |

850 LBS |

|

Weight w/Stand: |

975 LBS |

|

Shut Height: |

8” +/- 3/8” Adjustment |

|

Throat: |

6” |

|

Bolster Plate: |

14” W x 10” D |

|

Stroke: |

1.5” |

|

Ram Size: |

2” |

|

Ram Bore: |

¾-10 x 1-1/2” DP |

|

Operating Pressures: |

50-125 PSI |

|

Recommended Pressure: |

100 PSI |

|

Strokes Per Minute: |

30 |

|

Max Force Rating: |

60,000LBS at 0.010” from bottom of stroke. |